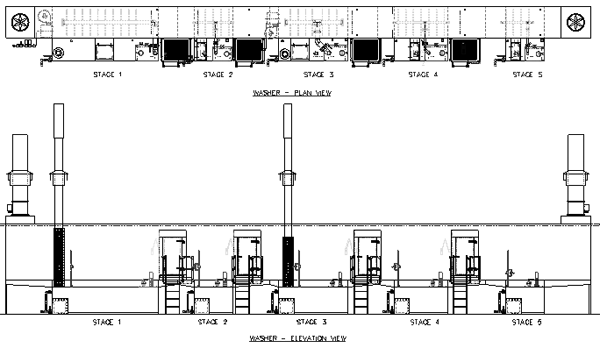

RAPID™ custom pre-treatment washers for paint finishing and powder coating systems are designed for pre-treatment of parts in a continuous powder coat or wet coat finishing system. These custom industrial spray washers consist of a series of pre-treatment washer tanks that are connected together with a tunnel that rests on top of the tanks. Inside the tunnel, parts travel via conveyor to be pre-treated prior to finish coating.

RAPID™ custom pre-treatment washers for paint finishing and powder coating systems are designed for pre-treatment of parts in a continuous powder coat or wet coat finishing system. These custom industrial spray washers consist of a series of pre-treatment washer tanks that are connected together with a tunnel that rests on top of the tanks. Inside the tunnel, parts travel via conveyor to be pre-treated prior to finish coating.

Each pre-treatment washer tank contains a pump and spray risers to spray the solution as the part travels past. In between clean and rinse zones, the part drains, allowing the tanks to reclaim the solution. Some tanks are heated depending on the process requirements. Standard heating is done with a direct-fired gas burner firing into a serpentine burner tube immersed in the solution. Other heating options include steam or electric.

On each end of the tunnel, exhaust fans are used to evacuate the water vapor generated by the cleaning process. Control is provided by a control panel with traditional relay logic or sophisticated PLC controls.

In higher volume production, the parts are loaded on a conveyor and transported through each process. These custom conveyorized parts washers are ideal for this application as each process and part requires a unique pre-treatment spray station optimized for that particular production application. Many custom pre-treatment parts washers are also designed with some flexibility towards future paint or powder coat finishing needs.

RAPID™ Custom Pre-treatment Washers for Paint Finishing and Powder Coat Systems – Cleans and Pre-treats Assemblies of Various Shapes and Sizes

An eight (8) stage zinc phosphate pre-treatment, industrial spray washer